본문

TGV Inspection Solution:

Completed with Ultra-Precise AF + High-Brightness Lighting

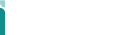

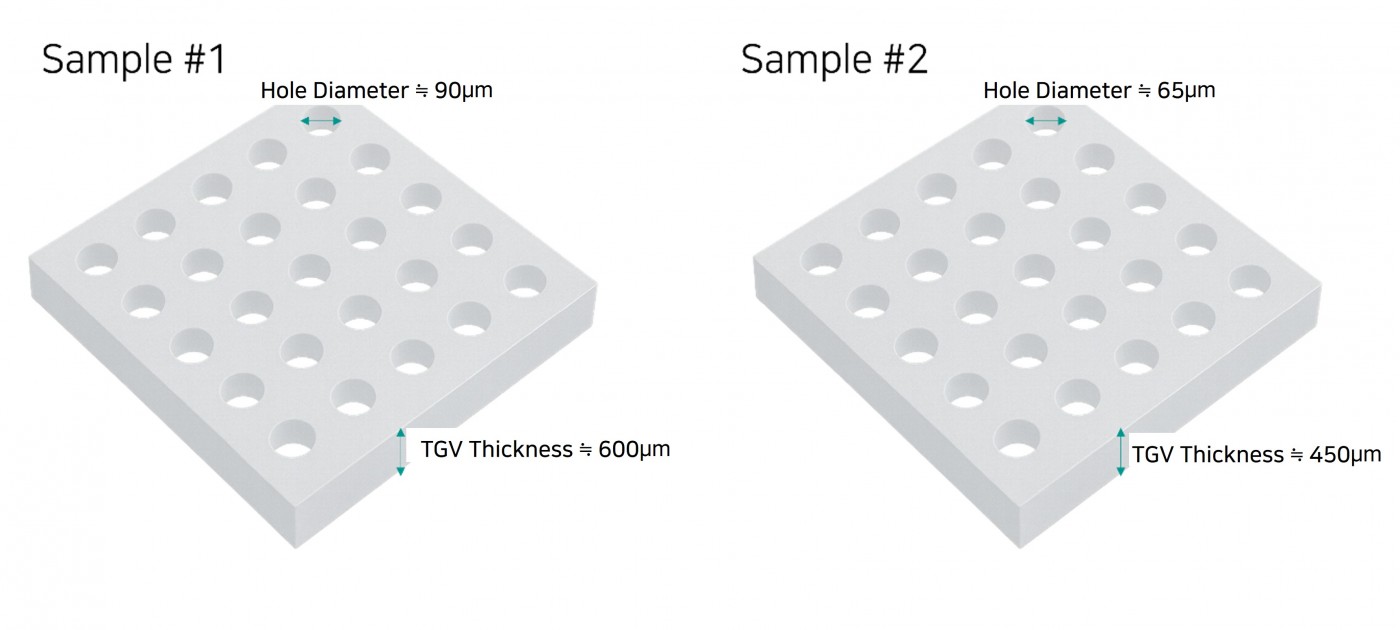

What is TGV (Through Glass Via)?

TGV is a high-density wiring technology that creates electrical connections by drilling micro-holes in glass substrates. Compared to traditional PCBs, it dramatically reduces signal delay and power loss.

TGV technology is gaining attention in semiconductor and packaging fields demanding high speed and high performance, such as 5G, AI, and High-Performance Computing (HPC).

In TGV manufacturing, microscopic holes of tens of micrometers must be inspected within glass substrates hundreds of micrometers thick. This requires high-resolution imaging and precise depth control. The inspection difficulty is heightened because both accuracy and speed must be ensured simultaneously.

Thus, Auto Focus (AF) technology and optimized lighting systems are key factors that determine inspection quality.

✅ Two Core Technologies That Determine TGV Inspection Quality

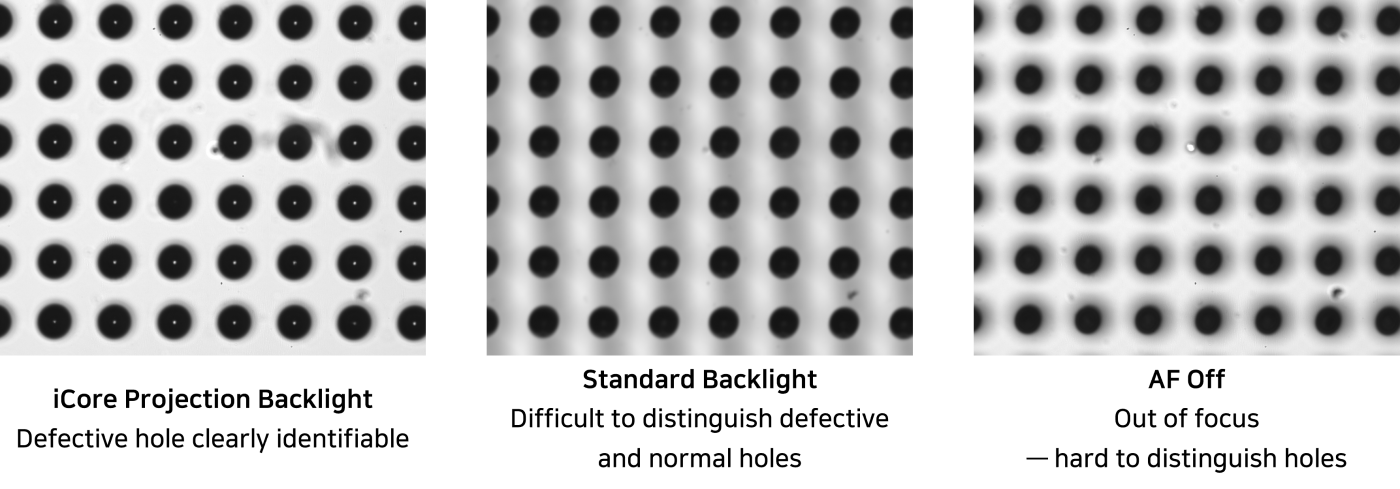

1. AF Technology for Accurate Focus Maintenance

Since hole shapes and sizes vary by layer, precise focus adjustment is essential in TGV inspection. Using high-magnification lenses results in a shallow depth of field, increasing the likelihood of focus errors. Therefore, a fast and precise AF system is a critical technology that enhances inspection accuracy.

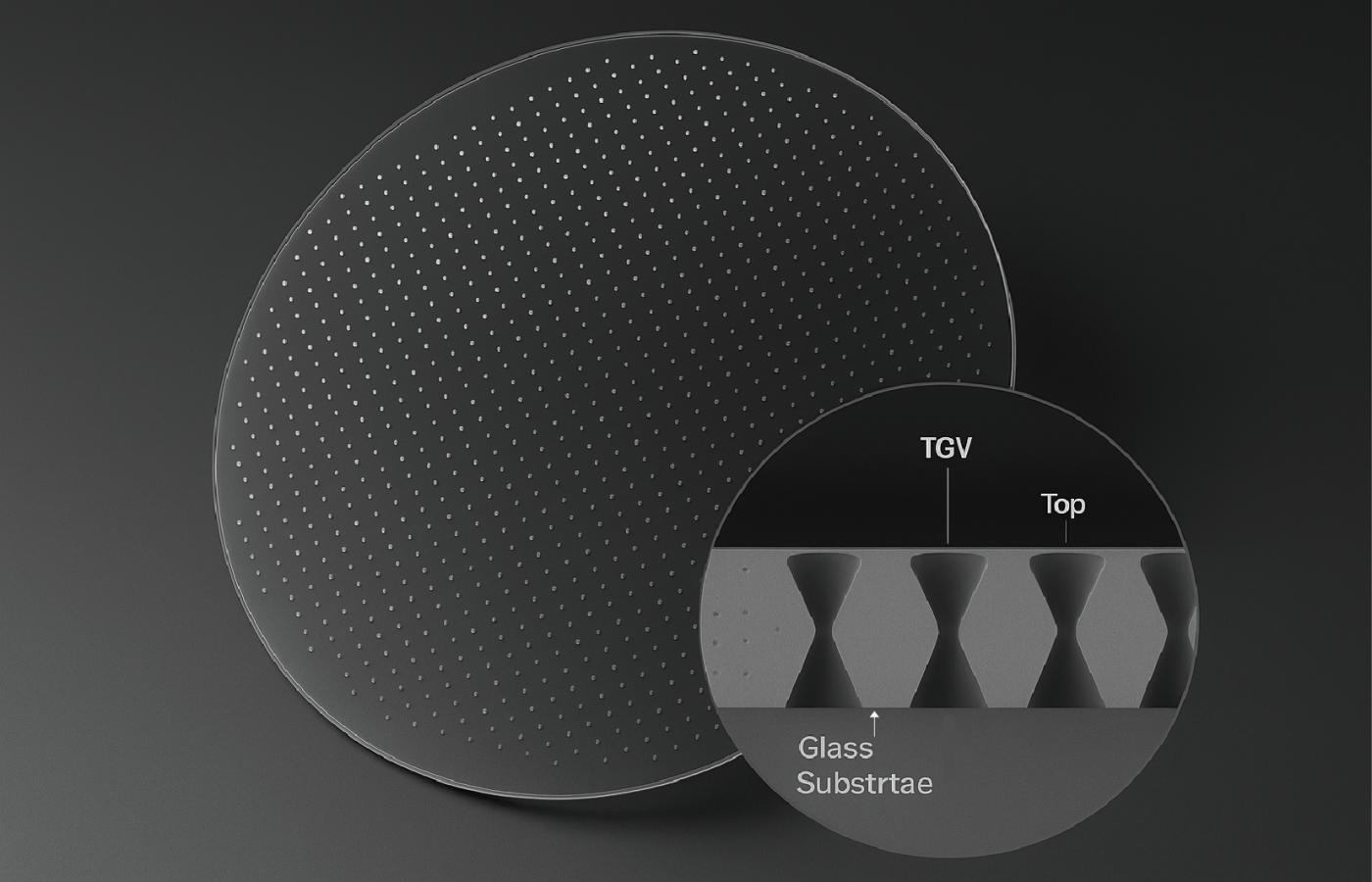

2. Lighting Technology to Secure Hole Contours

If the internal shape of holes is blurred or edges are unclear, analysis becomes difficult. Optimal lighting considering directivity, wavelength, and intensity ensures sharp contours and improves defect detection capabilities.

The images below show how defect hole detectability varies depending on AF status and lighting conditions.

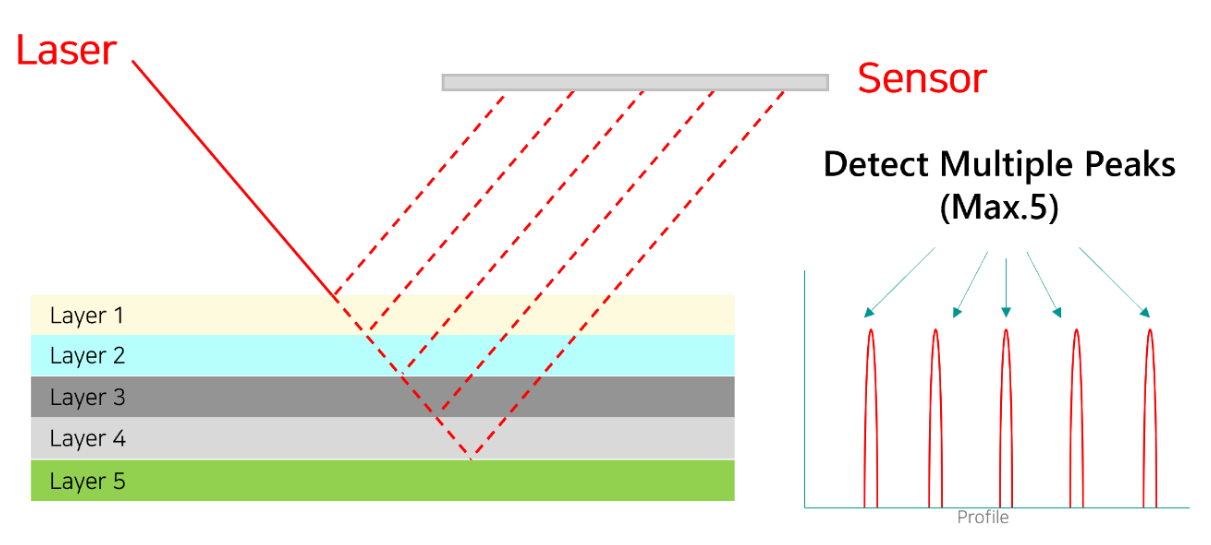

✅ iCore’s Auto Focus Solution

What is Auto Focus?

Auto Focus (AF) automatically adjusts the lens position based on the inspection target’s height to maintain focus in optical systems. In industrial inspection, where tiny patterns abound, AF precision directly impacts inspection quality.

The images below compare the cases when AF is ON (above) and OFF (below) while focusing.

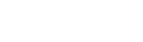

Triangulation AF Technology: Optimized for TGV Inspection

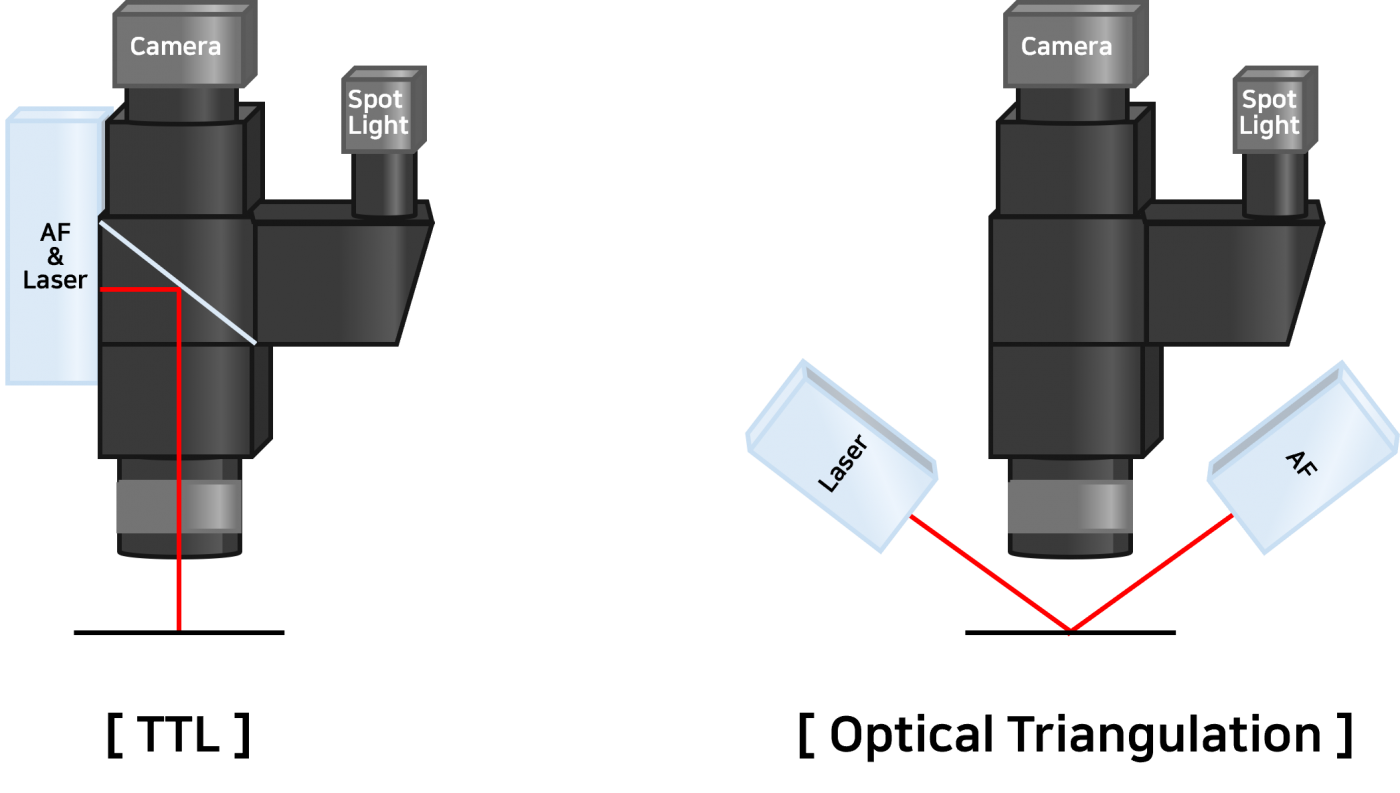

There are two main AF methods:

• TTL (Through The Lens): Laser, camera, and lighting are coaxially aligned.

• Optical Triangulation: The laser module and sensor are independently located beside the lens, detecting reflected light at an oblique angle.

Both use reflected laser light to adjust focus, but triangulation offers advantages in selecting focus per layer and maintaining focus on hole internal structures. TTL’s vertical laser irradiation can lose reflected light inside holes, while triangulation’s oblique angle enables stable measurement without reflection loss.

Thus, triangulation is the preferred AF solution for multilayer TGV hole inspection.

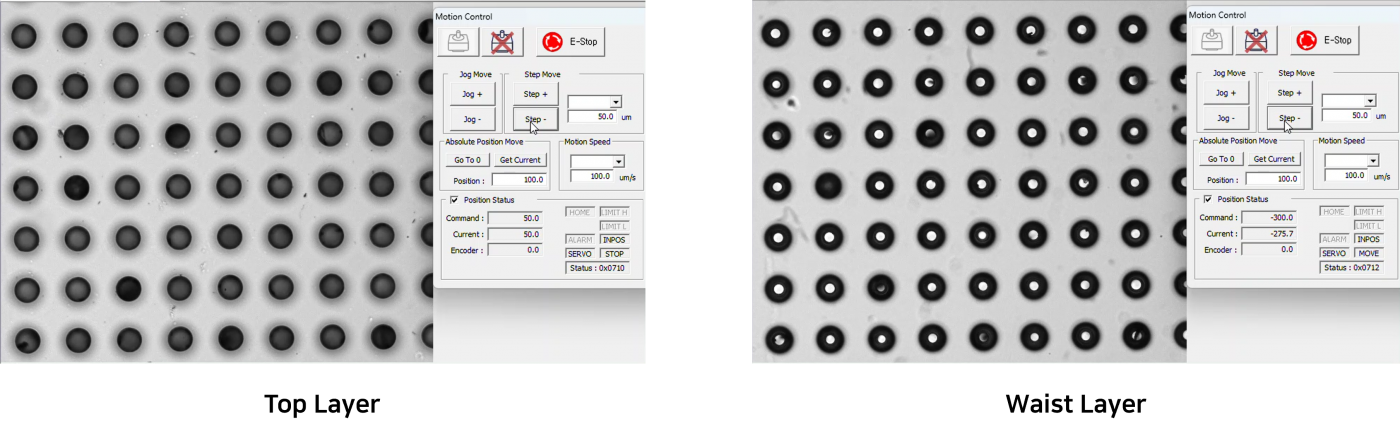

TGV structures generally consist of three layers: Top, Waist (middle), and Bottom.

iCore’s triangulation AF technology recognizes and distinguishes multiple layers via reflected laser signals, enabling automatic focus adjustment based on a selected layer.

The Waist layer is a middle region inside the hole without a distinct physical interface, often lacking clear laser peaks. Inspectors input offset values relative to reference layers like Top or Bottom, visually exploring this region.

This flexible multi-layer detection combined with offset functionality enables fast and stable metrology in precise inspection environments.

Real-Time Offset Function

In TGV inspection, switching focus according to the layer is frequent. Since the Waist region lacks clear interfaces and is difficult to detect directly by laser AF, focus is adjusted by calculating relative distance offsets from well-defined reference layers like Top or Bottom.

For example, if an inspector judges the Waist is 300μm below the Top, inputting an offset of -300μm moves the AF module instantly to that position. The AF system automatically adjusts the Z-axis without re-searching, enabling quick focus switching.

This reduces alignment time in continuous production, improving both process efficiency and inspection precision.

iCore’s Lighting Solution

Lighting in TGV inspection is not merely about brightness; it is essential for accurately recognizing hole depth and shape, ensuring inspection reliability. Even with perfect focus, inadequate lighting can blur shapes or miss defects.

iCore provides lighting solutions capable of delivering stable images under diverse conditions, optimized for precision inspection.

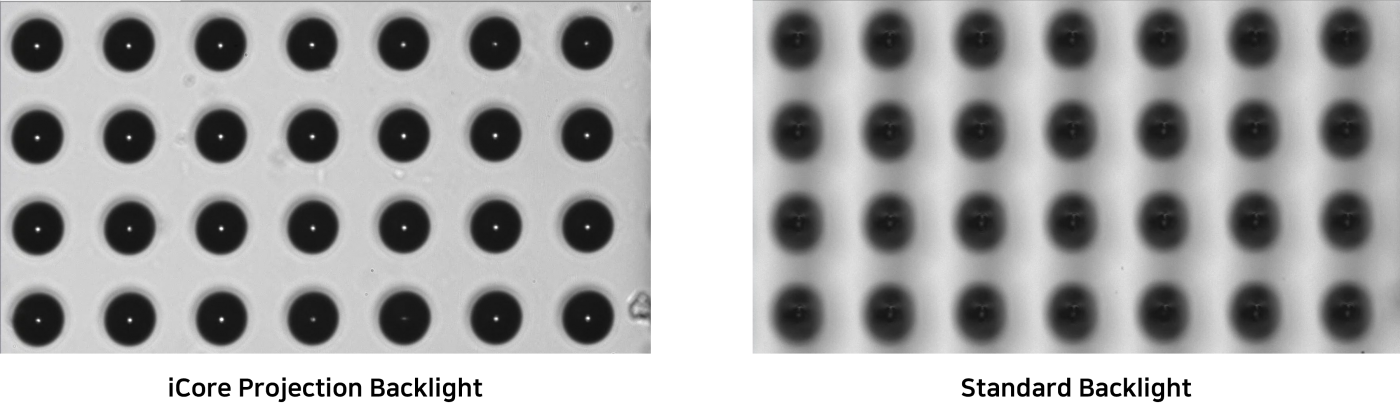

Projection Backlight Solution

General LED backlights struggle to meet TGV imaging quality demands. iCore applies high-performance projection-type lighting technology.

Projection Backlight Features

• Superior directivity compared to standard backlights, delivering sharp hole edge delineation.

• Telecentric-like light characteristics enabling high-precision contour recognition.

• Uniform, distortion-free imaging even at high magnifications.

The images below show the Waist layer (-220µm) of the same sample under conventional backlight (left) and iCore projection backlight (right), demonstrating the impact of lighting conditions on inspection accuracy.

[Image 6. iCore Projection Backlight (left) vs Standard Backlight (right)]

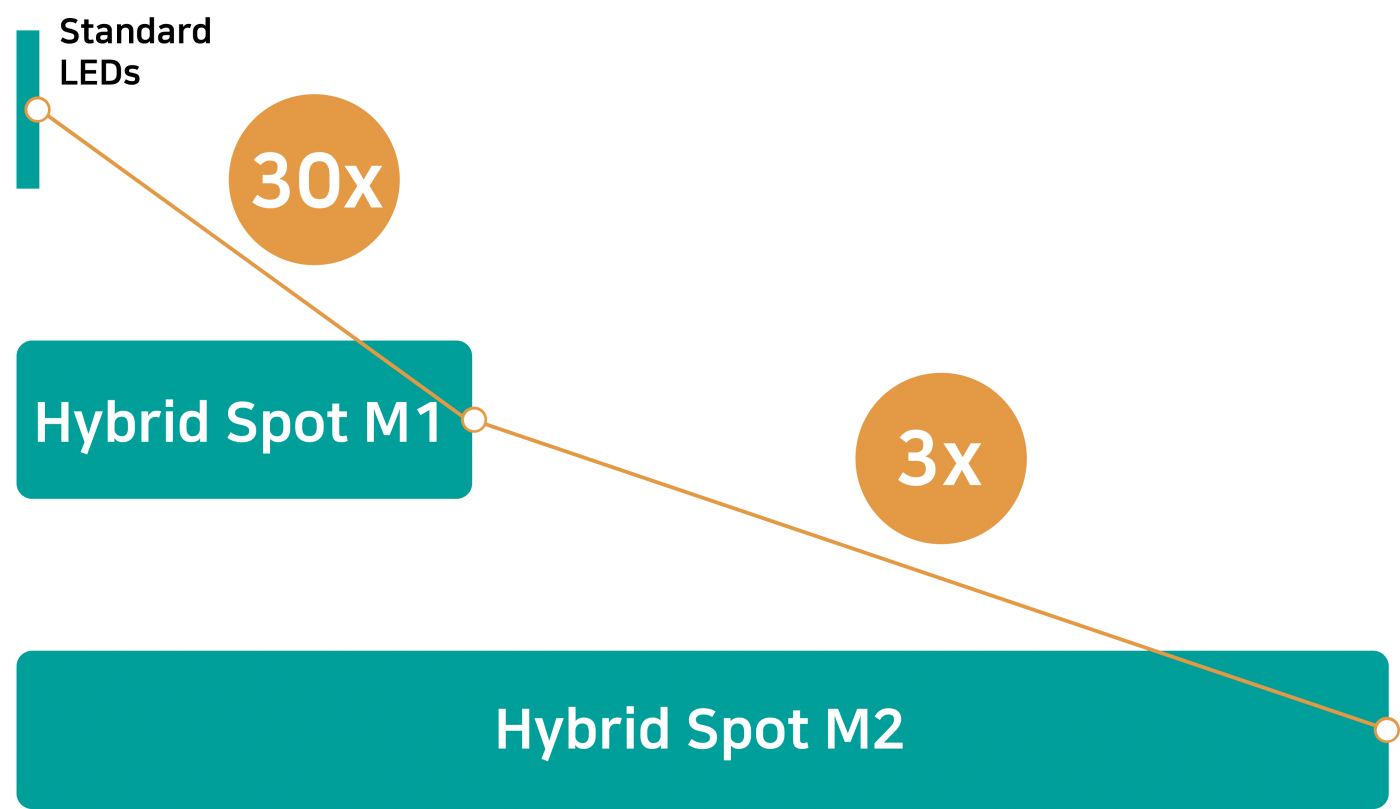

High-Brightness Hybrid Spot Light Solution

While projection-type backlight effectively secures high-contrast hole contours, exceptions exist:

• When installing backlight behind the sample is structurally difficult.

• When coaxial lighting is better for defect judgment.

• When combined backlight and coaxial lighting are needed for complex inspection.

Hybrid Spot Light

• Hybrid Spot M1 : Approximately 30 times brighter output than conventional LEDs.

• Hybrid Spot M2 : Three times brighter than M1, excelling where illumination intensity is critical.

Overdriving Technology:

iCore’s iPulse strobe controller safely applies short, over-rated currents to LEDs, momentarily maximizing light intensity. This enables:

High-resolution imaging in high-speed inspection environments, difficult with continuous light.

Stable image quality in complex lighting setups.

✅ iCore’s Technological Differentiation

Based on precise AF and high-performance lighting, iCore delivers differentiated technology competitiveness that meets the demanding precision and speed requirements of complex inspections like TGV.

With in-house developed technologies, iCore reduces reliance on expensive overseas equipment, offering flexible, customer-tailored solutions rapidly.

This technological strength goes beyond component supply, forming a core foundation enhancing Korea’s semiconductor and display inspection ecosystem competitiveness. iCore continues to lead domestic high-precision inspection technology localization as a key partner.

[Image 8. iCore Optical Triangulation AF module]

Specs | Details |

Camera | 5M Area Camera |

Pixel Size | 3.45μm |

Lens | M Plan APO 10x |

Resolution | 0.345μm |

[Table 1. Test Conditoin]

[Image 9. TGV Sample]