Applications

Smart Factory

As the industrial production system changes with customized mass production, the manufacturing industry is adopting smart factories as a new method of manufacturing innovation. When applied to smart factories, iCore's solutions can further improve productivity, product quality, and customer satisfaction, etc.

Battery Inspection

As the use of Secondary Cell gradually expands in various fields, the need for inspections that take into account different product characteristics and processes, as well as the demand for high-accuracy vision inspection equipment are increasing. iCore is equipped with vision inspection equipment that uses precise cameras capable of detecting even the smallest defects in products.

Display

Existing algorithms have their limitations in detecting defects that occur during display manufacturing. iCore's solution uses a deep learning algorithm to maximize production yield and offers an optical system solution that may be applied to all fields of diverse and demanding display manufacturing processes.

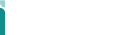

Semiconductors

Machine Vision systems are used in the visual inspection of high-tech precision materials and semiconductors which are key components of many products. iCore's Machine Vision system is able to conduct precise measurement of inconspicuous fine dents or cracks between circuit boards. It also increases the processing rate of inspection equipment and minimizes the time required for inspection.

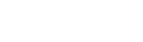

Automobiles

In response to short lead times, tight inventory management, complex supply chains and OEM's zero-defect requirement, automakers are adopting machinevision technology throughout their production facilities to address these challenges.

Electronic Parts

Quantitative surveying of fixed images requires a machinevision system. iCore's machinevision system is able to inspect hundreds or even thousands of parts on a production line per minute and examine in detail matter invisible to the human eye.